MIL-DTL-62006C(AT)

3.4.1 Leakage. Cooler assemblies and cores shall not leak when subject to 400 pounds

per square inch (psi) of hydrostatic pressure for at least 10 minutes, and 15 000 hydraulic pressure

cycles from 0 to 300 psi.

3.4.2 Heat rejection. Heat rejection for the cooler assemblies and cores shall be not less

than as specified in table II.

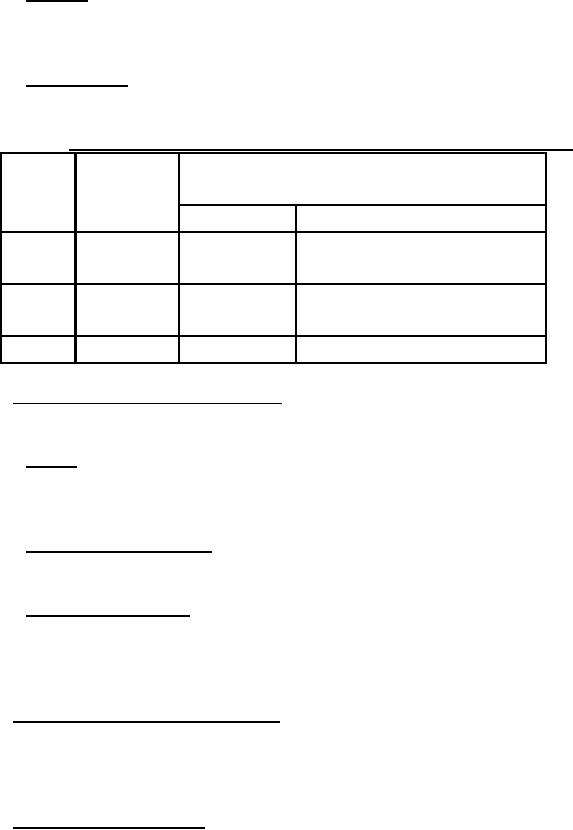

TABLE II. Heat rejection for engine and transmission cooler cores and assemblies.

Heat rejection-British thermal units (Btu)

(kiloJoules/minute)

Type

Class

(see 1.2)

(see 1.2)

Engine

Transmission

I

A

2729 (2880)

---

B&C

---

6484 (6840)

II

D

1354 (1430)

1643 (1735)

E

1266 (1335)

1563 (1650)

III

F&G

5280 (5570)

9525 (10050)

3.5 Support and ownership requirements. Cooler assemblies and cores shall possess the

following life cycle ownership characteristics.

3.5.1 Safety. Cooler assemblies and cores shall not produce any hazards to personnel or

the environment resulting from the use of asbestos, cadmium, radioactive materials, toxic

chemicals, or other hazardous substances.

3.5.2 Contamination resistance. Cooler assemblies and cores shall withstand a jarring

drainage of mineral spirits without evidence of loose particles.

3.5.3 Identification marking. Unless otherwise specified (see 6.2), the cooler assemblies

and cores shall be marked with the National Stock Number (NSN), the manufacturer's

identification code (CAGE), and the part or identifying number (PIN) (see 6.5). Marking shall be

permanent and legible.

3.6 Operating environment requirements. Cooler assemblies and cores shall withstand

vibration through the frequency range as specified in figures 1 and 2.

4. VERIFICATION

4.1 Classification of inspection. The inspection requirements specified herein are

classified as follows:

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business