MIL-PRF-45085D

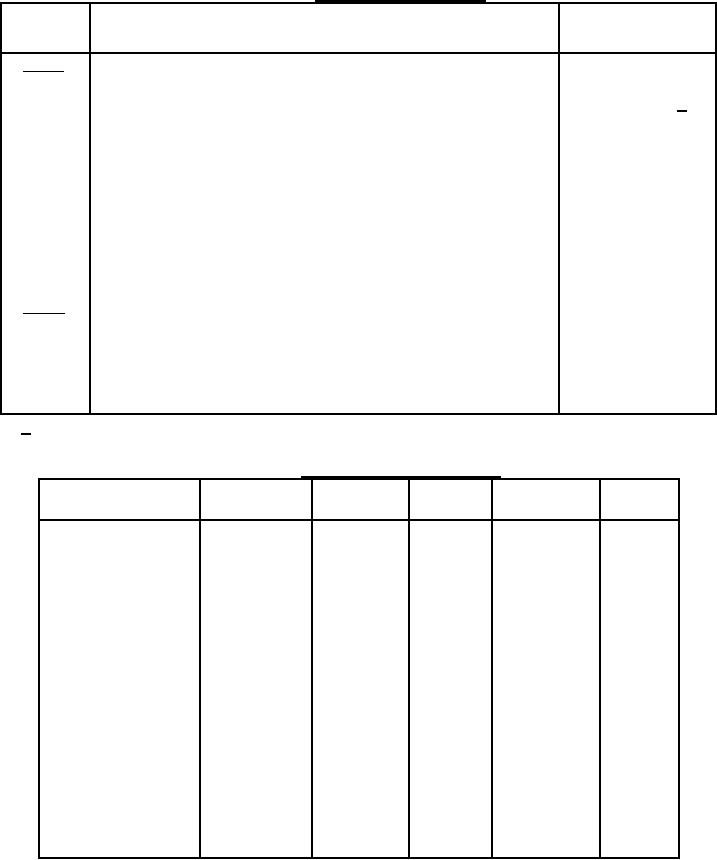

TABLE I. Classification of defects.

Method of

examination

Category

Defect

Major:

101

Brazing, improper method (see 3.3).

Visual

102

Tubes not as specified (see 3.3).

Visual & SIE 1/

103

Visual &

Corrosion and flux control - improperly removed (see 3.3.1).

Functional

Visual &

104

Internal preservation treatment - insufficient protection (see 3.3.2).

Functional

Visual

105

Paint pretreatment - improperly performed (see 3.3.3).

106

Dimensions affecting interchangeability - out of tolerance (see 3.3.4).

SIE & Functional

107

Workmanship affecting performance - insufficient (see 3.6).

SIE & Functional

Minor:

201

Painting - improper application or finish (see 3.3.3).

Visual

202

Dimensions not affecting interchangeability - out of tolerance

SIE

(see 3.3.4).

203

Marking - illegible or improperly performed (see 3.5).

Visual

204

Workmanship - improperly performed (see 3.6).

Visual

1/ SIE = Standard Inspection Equipment.

TABLE II. Classification of inspections.

First

Control

Title

Requirement

Inspection

article

Conformance

test

3.2 thru 3.3.2

Materials &

4.5.1

X

construction

3.3.3, 3.3.4,

Defects (see table I)

4.5.2

X

X

X

3.5 & 3.6

Performance

3.4

4.5

X

Leakage (noncyclic)

3.4.1

4.5.4.1

X

X

Leakage (cyclic)

3.4.1

4.5.4.2

X

X

Hydrostatic pressure

3.4.2

4.5.4.3

X

X

Heat rejection

3.4.3

4.5.4.4

X

X

X

Heat rejection,

3.4.3.1

4.5.4.4.1

X

X

arrangement A

Heat rejection,

3.4.3.2

4.5.4.4.2

X

X

arrangement B

Heat rejection,

3.4.3.3

4.5.4.4.3

X

X

arrangement C

Vibration

3.4.4

4.5.4.5

X

X

Corrosion resistance

3.4.5

4.5.4.6

X

X

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business