MIL-PRF-45085D

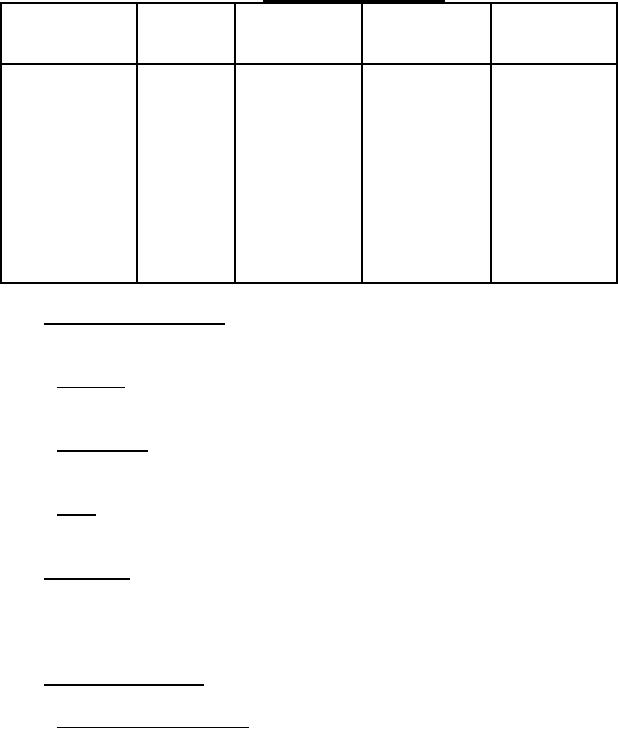

TABLE III. First article test sequence.

Core assembly,

Core assembly,

Oil cooler

Test

engine oil,

transmission oil,

assembly,

sequence

Inspection

configuration A

configuration B

configuration C

Leakage

4.5.4.1

X

X

Cycling

4.5.4.2

X

X

Vibration

4.5.4.5

X

X

Corrosion

4.5.4.6

X

X

Hydrostatic

4.5.4.3

X

X

X

Heat rejection,

4.5.4.4.1

X

configuration A

Heat rejection,

4.5.4.4.2

X

configuration B

Heat rejection,

4.5.4.4.3

X

configuration C

4.3 Conformance inspections. Conformance inspections shall include the examinations of

4.3.2 (see table I) and the tests of 4.5.4 through 4.5.4.6 (see table II).

4.3.1 Sampling. Samples for conformance inspection shall be selected in accordance with

ANSI/ASQC Z1.4.

4.3.2 Examination. Samples for examination inspection shall be in accordance

with Table I.

4.3.3 Tests. Each sample shall be tested for compliance with the requirements specified

in 3.4.1.

4.4 Control test. When specified (see 6.2), control test samples shall be selected at the

rate of 2 assemblies from each 500 units of one configuration produced, except that not more than

4 or less than 2 samples shall be selected in any 30 day period. The control test samples shall be

subjected to the examination and control tests specified in table II.

4.5 Methods of inspection.

4.5.1 Materials and construction. Conformance to 3.2 thru 3.3.2 shall be determined by

inspection of contractor records providing proof or certification that design, construction,

processing and materials conform to requirements. Applicable records shall include drawings,

specifications, design data, receiving inspection records, processing and quality control standards,

vendor catalogs and certifications, industry standards, test reports, and rating data.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business