MIL-PRF-62259B

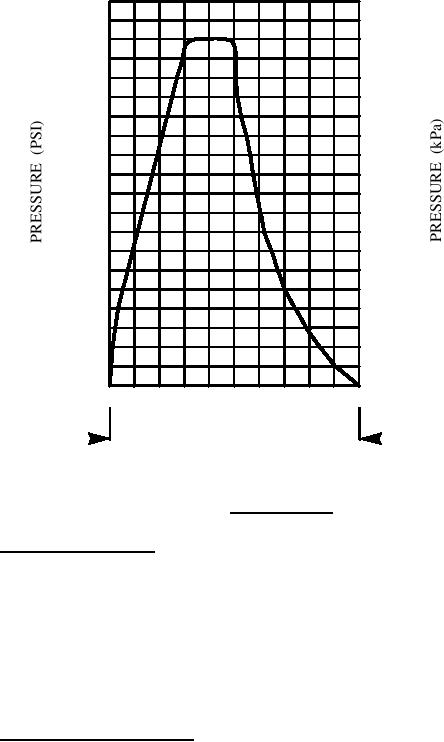

at 0 psig and rise to 18 psig (124.1 kPa), swell a minimum of two seconds above 17 psig

(117.2 kPa) and return to 0 psig. At the end of the 10 000 cycles, there shall be no evidence of

rupture or leakage when the radiator is pressurized to 18 psig (124.1 kPa) under water. Evidence

of leakage shall be cause for rejection.

137.8

20

124.1

18

16

110.2

96.5

14

82.7

12

68.9

10

55.2

8

41.4

6

27.6

4

13.8

2

0

1

34

5

67

8

9 10

2

SECONDS

O N E CYCLE TIME

FIGURE 5. Pressure cycle.

4.3.3.5 Pressure capacity test. To determine conformance to 3.3.5, all radiators shall be

subjected to a pressure capacity test. The inlet and outlet ports shall be plugged and a suitable

pressure cap substituted to withstand the test pressure. An air injection nozzle shall be installed in

either the inlet or outlet plug. Air pressure of 18 psig (124.1 kPa) shall be injected into the

radiator and maintained for 30 seconds with radiator submerged in water. All radiators showing

any sign of air bubbles by leakage, or restriction in coolant flow shall be cause for rejection.

Repairs are permitted. Any radiator requiring repair shall be retested with the rejection criteria

applicable as stated above.

4.3.3.6 High pressure capacity test. To determine conformance to 3.3.6, radiators shall be

subjected to a high pressure capacity test. The inlet and outlet ports shall be plugged and a

suitable pressure cap substituted to withstand the test pressure. An air injection nozzle shall be

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business