MIL-PRF-62259B

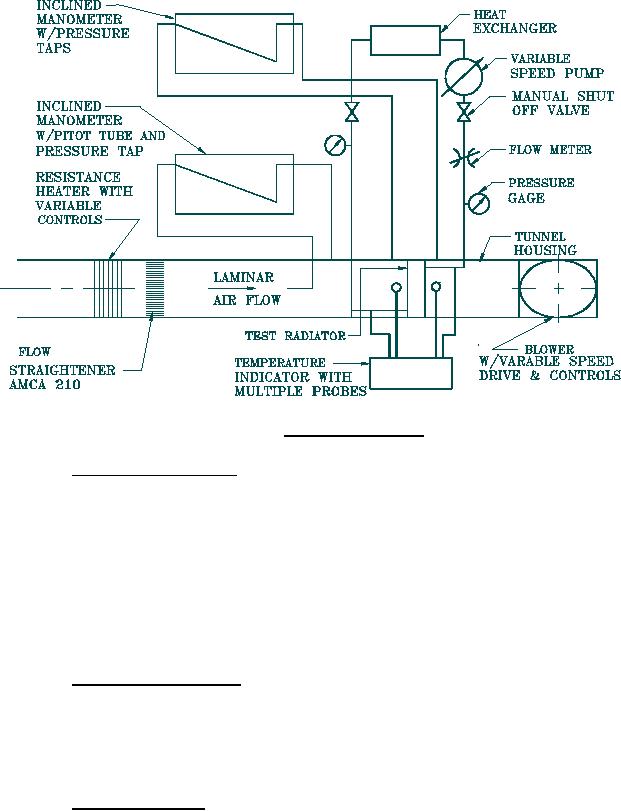

FIGURE 4. Alternate test setup.

4.3.3.2 Air flow resistance test. To determine conformance to 3.3.2, the radiator shall be

connected to a test setup similar to that shown in figure 3 or figure 4. With the system operating

as specified in 4.3.3.1, the air pressure drop across the radiator shall be measured at the same

time as the corresponding heat capacity. The pressure taps shall be in planes parallel to, and not

more than 4 in. (101.6 mm) from, the faces of the core. The air shall be measured in inches of

water (kPa) at an air density of 0.075 pounds per cubic foot (lb/ft3) (1.20 kilogram per cubic

meter (kg/m3)). The air flow resistance shall be based on the unobstructed area of the core and

the average inlet velocity is to be measured within three percent. Air flow values obtained from

testing which are greater than those shown on figure 1 shall constitute failure of the test.

4.3.3.3 Coolant flow resistance. To determine conformance to 3.3.3, the radiator shall be

connected to a test setup similar to that shown in figure 3 or figure 4. With the system operating

as specified in 4.3.3.1 and with a volume flowrate of the coolant of 94 gal/min (5.9 L/s), as

measured between the radiator inlet and outlet. A measured pressure drop across the inlet and

outlet ports of more than 3.0 psi (20.7 kPa) shall be cause for rejection.

4.3.3.4 Pressure cycle test. To determine conformance to 3.3.4, the radiator shall be

positioned and operated in its normal vehicle position in an ethylene glycol circulatory system.

Ethylene glycol shall conform to A-A-52624. The system shall maintain the ethylene glycol at a

maximum temperature of 250°F ± 10°F (121°C ± 6°C) measured at radiator inlet and outlet. The

radiator shall be subjected to the air pressure cycle approximated in figure 5. A cycle shall begin

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business