MIL-PRF-62259B

3.2.1 Recycled, recovered, or environment preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided the

material meets or exceeds all specified requirements and promotes economically advantageous life

cycle costs.

3.3 Operating requirements.

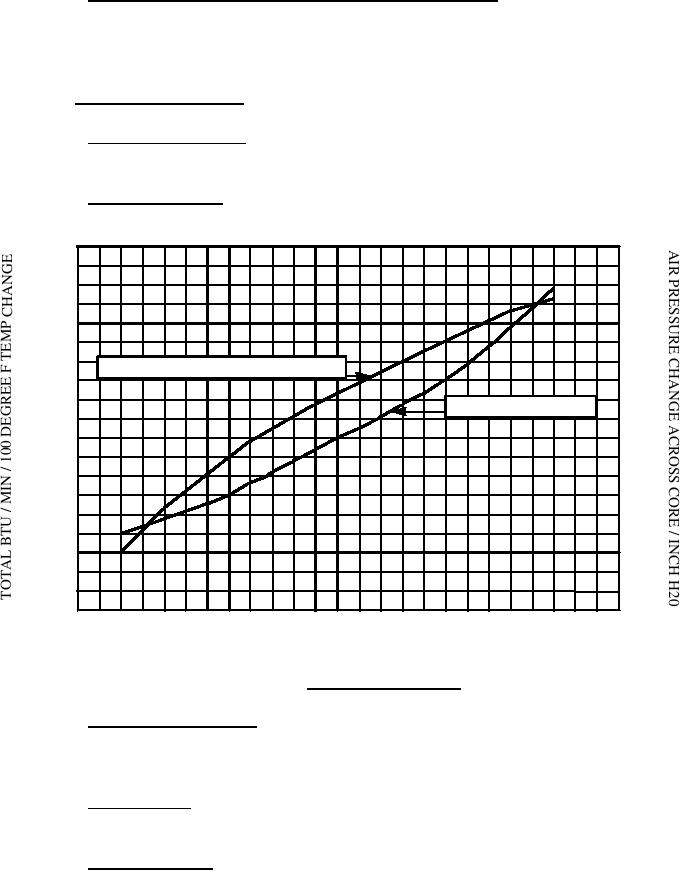

3.3.1 Heat transfer capacity. The heat transfer capacity, based on the unobstructed area

of the core, shall not be less than shown on figure 1.

3.3.2 Air flow resistance. The maximum static air flow resistance shall not be more than

that shown on figure 1.

16000

7.0

6.5

14500

6.0

5.5

13000

5.0

BTU/MIN/100 DEG F CHANGE

4.5

11500

4.0

AIR RESISTANCE

10000

3.5

3.0

2.5

8500

2.0

1.5

7000

1.0

.5

5000

0

500

1000

1500

2000

2500

AIR FLOW \ LBS \ MIN (FACE VELOCITY) (AIR CORRECTED TO 0.075 LBS / CU. FT.)

FIGURE 1. Btu rating of radiator.

3.3.3 Coolant flow resistance. The maximum coolant flow resistance at 94 gallons per

minute (gal/min) (5.9 liters per second (L/s)) coolant flow rate shall not be more than 3.0 pounds

per square inch (psi) (20.7 kilopascal (kPa)).

3.3.4 Pressure cycle. Radiators shall withstand a minimum of 10 000 air pressure cycles

at 6 cycles per minute without rupturing or leaking.

3.3.5 Pressure capacity. Radiators shall withstand an internal pressure of 18 pounds per

square in gauge (psig) (124.1 kPa) for a period of not less than 0.5 minute (or approved alternate

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business